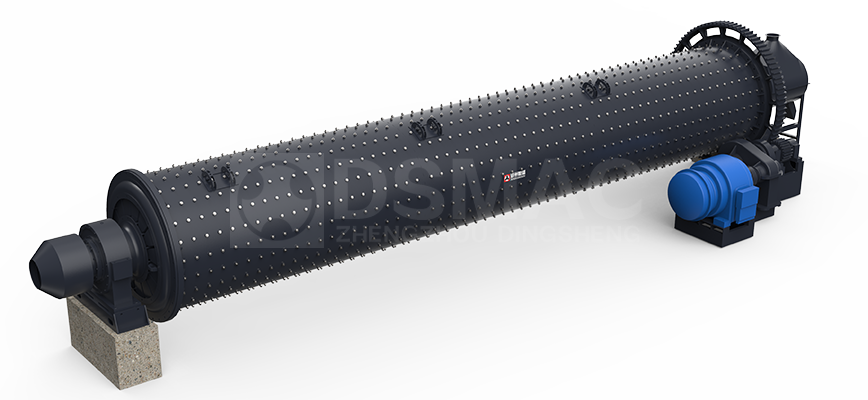

The MB Rod Mill is a kind of mill with steel rod in the barrel. It is an asynchronous motor connected to a small gear through a reducer, directly driving the surrounding large gear to decelerate and rotate, driving the rotating part to rotate. The inside of the barrel is equipped with appropriate grinding media - steel rods. The material is continuously fed into the barrel from the feeding part. Under the impact of centrifugal force and friction force, it is crushed by the moving grinding medium, and then discharged from the rod mill by the power of overflow and continuous feeding, then proceed to the next step.

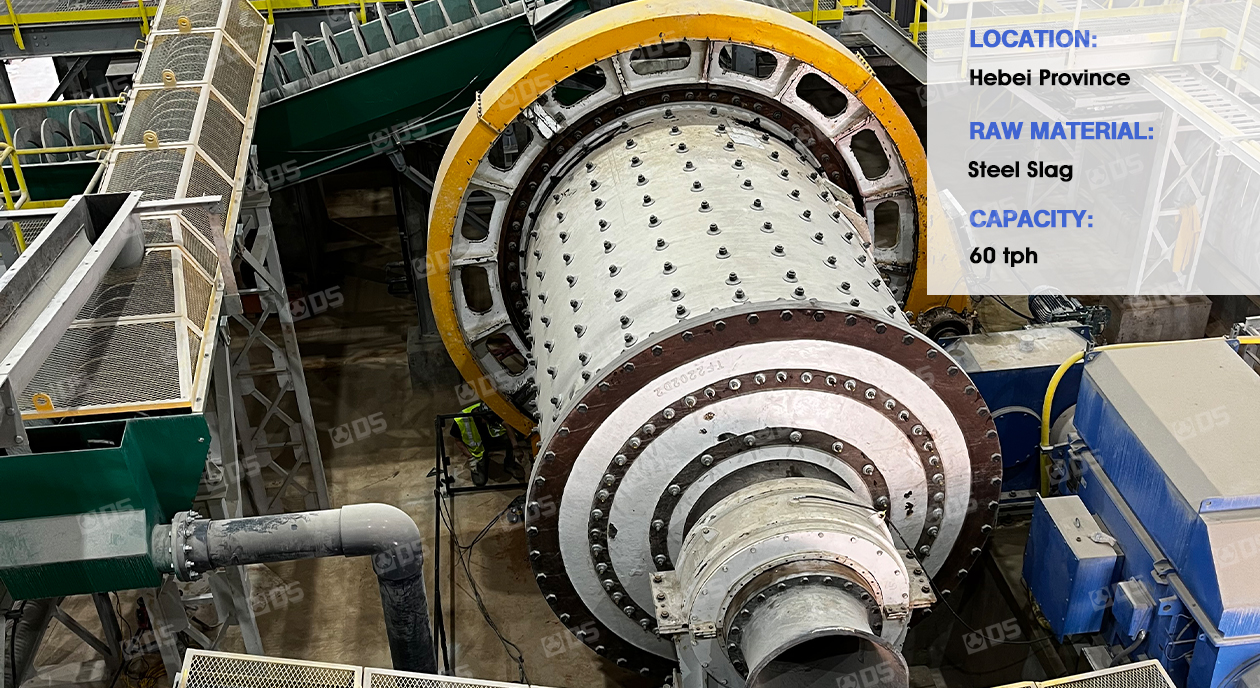

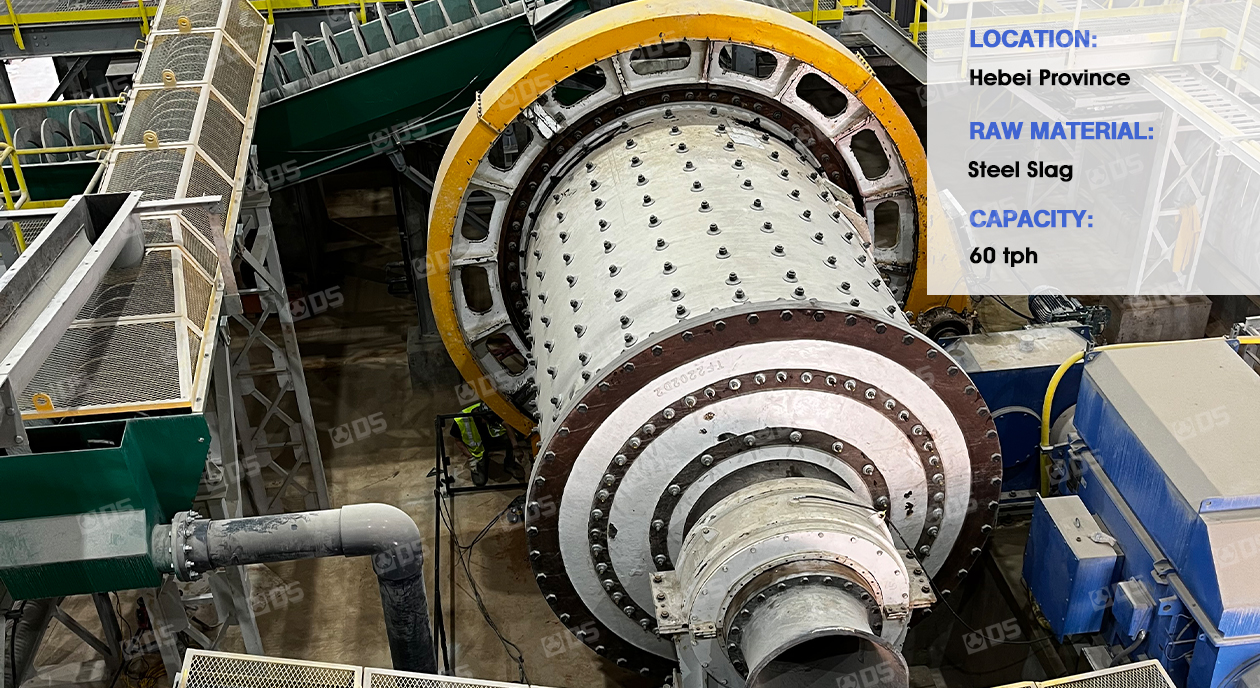

The rod mill is a significant equipment in steel slag recovery solution. Steel slag is the waste slag produced in the steelmaking process, and its output is 15%-20% of the crude steel output, and it accounts for a large proportion of the industrial waste slag. Some iron particles and iron powder are wrapped in steel slag, which can be recycled as raw materials for steelmaking. Recover more metallic iron from tailings through the metal deep purification production line, ensruing that the average content of elemental metallic iron in the tailings does not exceed 2%, and at the same time, obtaining the steel slag coarse powder and fine powder as raw materials for comprehensive utilization, thereby saving energy and reducing consumption in steel plants.

Two useful materials can be obtained after steel slag recovery and treatment:

1. The iron particles and iron powder are recovered and used for steelmaking.

2. The waste slag can be used as the raw material of cement to be sent to the cement plant.

| Model | Effective volume (m³) |

Cylinder speed (r/min) |

Motor power (kw) |

Weight (t) |

| Φ900×1800 | 0.9 | 35.4 | 22 | 5.37 |

| Φ900×2400 | 1.2 | 35.4 | 30 | 5.88 |

| Φ1500×3000 | 5 | 26 | 95 | 18 |

| Φ1500×3000 | 4.4 | 26 | 95 | 17.29 |

| Φ2100×3000 | 9 | 20.9 | 210 | 42.18 |

| Φ2100×3000 | 9 | 20.9 | 210 | 57 |

| Φ2700×3600 | 18.5 | 18 | 400 | 68 |

| Φ2700×4000 | 20.6 | 18 | 400 | 73.3 |

| Φ3200×4500 | 32.8 | 16 | 630 | 108 |

| Φ3600×4500 | 43 | 14.7 | 1000 | 159.9 |

| Φ3600×5400 | 50 | 15.1 | 1250 | 150 |