LIMESTONE 950-1000T/H

NOTE: This is NOT a Process Flow Diagram

The processing of limestone takes primary screening, crushing, secondary crushing and screening in the closed circuit of the process, and third-level screening, combined with soil removal, to produce qualified high-quality aggregate products. Hour processing capacity is set to 1000 tons. 2,750,000 to 3,000,000 tons of limestone are processed annually.

The finial product can be adjusted to your specific need.

The finial product can be adjusted to your specific need.

CASE OF LIMESTONE

SOUTH AFRICA - 1000T/H

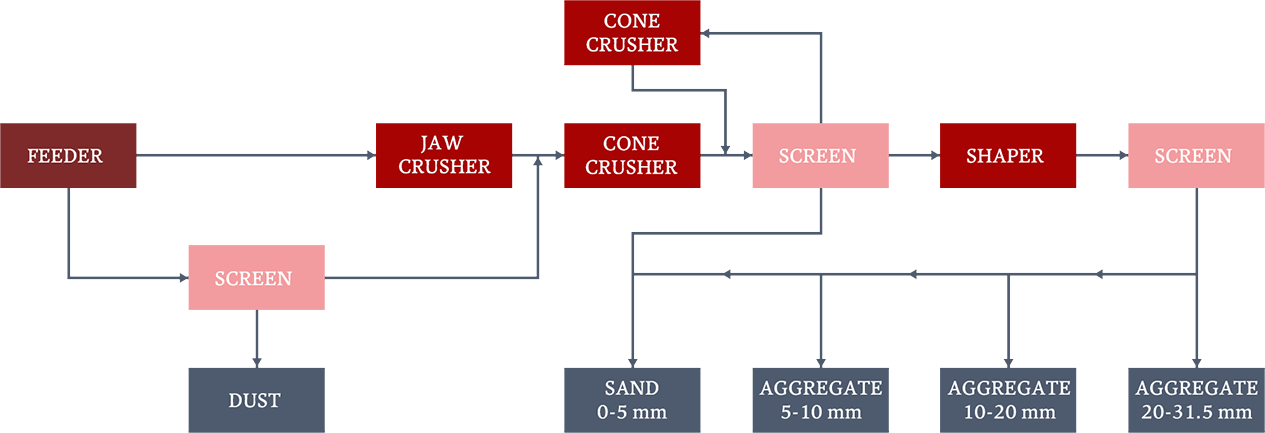

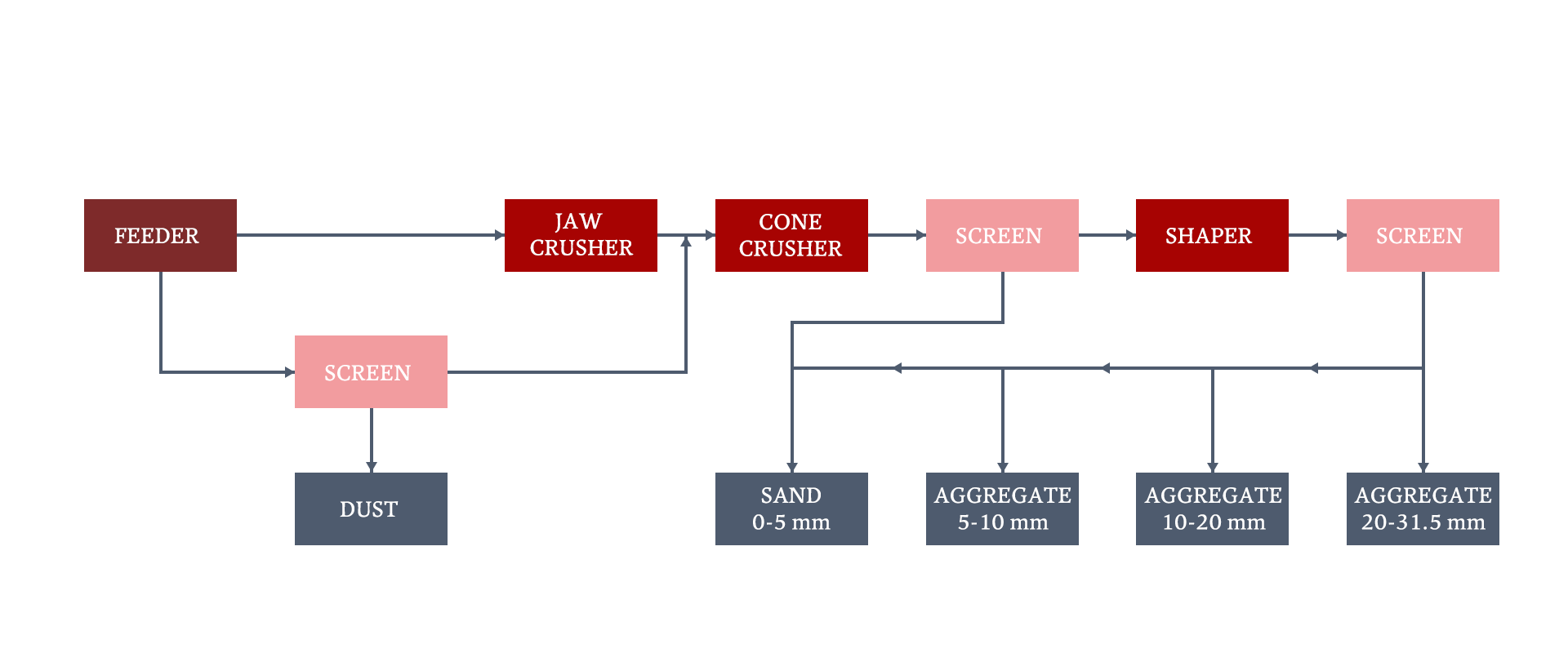

GRANITE 300-350T/H

NOTE: This is NOT a Process Flow Diagram

The processing of granite takes primary crushing, secondary dual crushing and primary secondary screening as well as a third-level shaping and screening in the closed circuit of the process, combined with soil removal, to produce qualified high-quality aggregate products. Hour processing capacity is set to 350 tons. 1,000,000 to 1,050,000 tons of granite are processed annually.

The finial product can be adjusted to your specific need.

The finial product can be adjusted to your specific need.

CASE OF GRANITE

CHINA - 350T/H

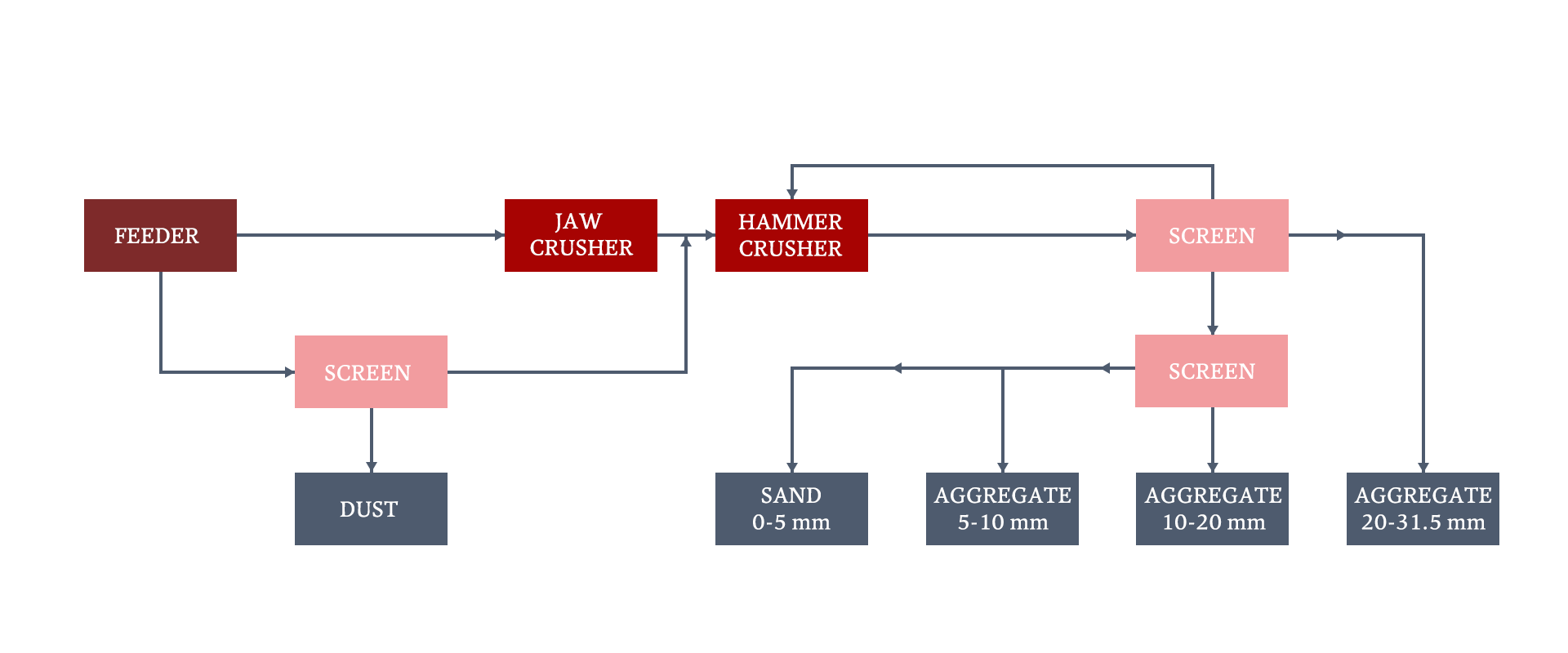

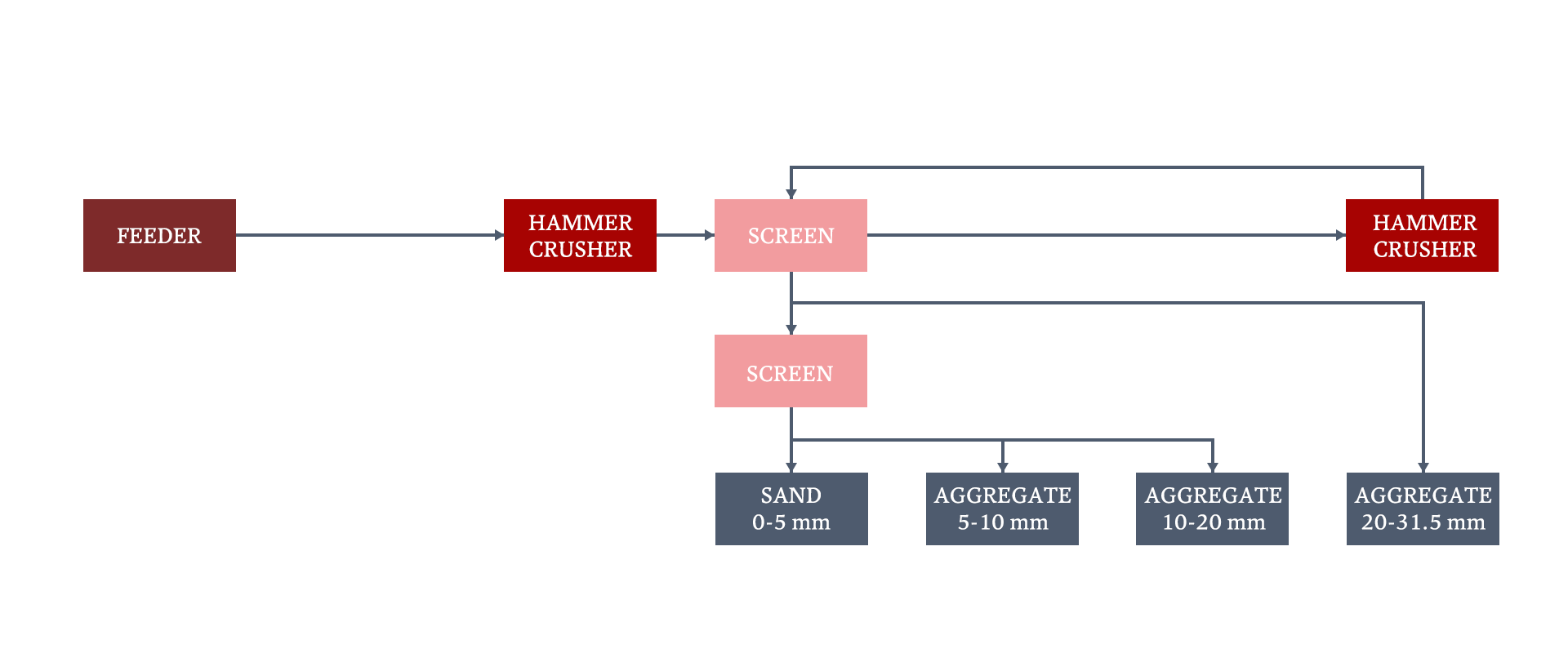

LIMESTONE 300-350T/H

NOTE: This is NOT a Process Flow Diagram

The processing of limestone takes primary crushing, primary secondary screening and secondary crushing in the closed circuit of the process, combined with soil removal, to produce qualified high-quality aggregate products. Hour processing capacity is set to 300 tons. 800,000 to 900,000 tons of limestone are processed annually.

The finial product can be adjusted to your specific need.

The finial product can be adjusted to your specific need.

CASE OF LIMESTONE

PAKISTAN - 300T/H

COBBLESTONE 200-250T/H

NOTE: This is NOT a Process Flow Diagram

The processing of cobblestone takes primary crushing, secondary crushing and primary secondary screening as well as a third-level shaping and screening in the closed circuit of the process, combined with soil removal, to produce qualified high-quality aggregate products. Hour processing capacity is set to 200 tons. 550,000 to 600,000 tons of cobblestone are processed annually.

The finial product can be adjusted to your specific need.

The finial product can be adjusted to your specific need.

CASE OF COBBLESTONE

SRI LANKA - 200T/H

INTERESTED IN OUR SOLUTIONS? YOU CAN CHECK OUT MORE ABOUT THOSE PRODUCTS

ON THEIR INDIVIDUAL PAGES OR CONTACT US FOR MORE.

.png)